Today, different roof systems are used to build the roof of a building. Due to the increased safety of the building against natural disasters such as earthquakes, engineers and architects try to use light roof systems for the roof of the building. These systems do not put a dead load on the structure and reduce the risks of natural disasters by being lightweight. Ubot and Cubiax roofing systems are among the systems for implementing hollow roofs with durable molds, but another type of roofing system called waffle is also implemented in the construction industry today, which can be implemented with non-durable molds in construction projects.

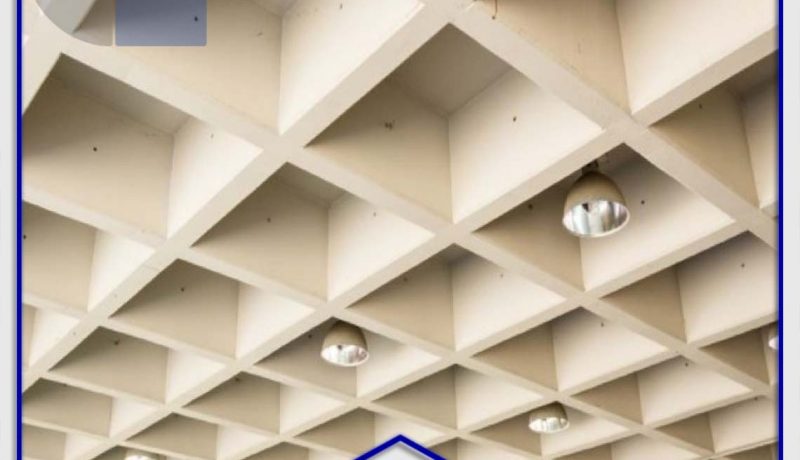

Waffle roof

Waffle roofs are grid and pot-shaped roofs that are used to cover large openings. The function of this type of roof is like a double-sided slab and there is no need for reinforcement rebars and their connection to the beams. The shape of this type of roof is cubic and hollow and is used in different dimensions according to the project. Waffle molds are made of composite plastic and are lightweight so that they are very easy to carry by workers. Waffle roofs can be used in a variety of metal and concrete skeletons. The molds of this type of roof make it possible to implement the roof as a one-way or two-way slab by changing the way they are assembled.

Features of waffle molds

Waffle molds can be separated from concrete after roof concreting operations and can be used again in other construction projects. One of the features of this type of template is its renewal, which can be recycled after the useful life of these templates. The use of these composite molds increases the durability and strength of the roof and makes the structure lighter, which makes the building safer against natural disasters such as earthquakes. These molds allow the removal of roof blocks from the building, which is a reason to lighten the structure.

Waffle roof substructure

Waffle roofs are easier to install than other concrete roofs. The substructure of this type of roof is similar to the roof of beams and blocks, and the substructure can be done with metal cans, scaffolding pipes, wood and four lathes and other accessories. The design of waffle molds is such that the beams can be applied in place. Using this method of roof construction, double beams can be removed, which reduces the weight of the concrete and lightens the structure. By running the beam in place, there is no need to move the beam in the main beams when closing the beam reinforcement. When the beams are executed in place, the connection between the concrete and the rigidity of the roof is well observed, which reduces the vibration of the roof during operation.

Advantages of Waffle Roof Execution

With this type of roof, the facilities can be passed through the roof, which reduces the thickness of the flooring and reduces construction costs and makes the structure lighter.

Waffle molds are one of the most durable molds for the roof, which allows you to reuse the molds and reduce costs.

Waffle molds do not need to be greased to separate from the concrete, and concrete processing can be ensured until the mold is opened.

Waffle roofs are lightweight ceilings, and their low weight causes low vibration and reduces the amount of transmission.

The ceiling, which is made using a waffle system, weighs ten centimeters on a flat slab.

The execution of this type of roof is in the form of beams, which is done without the use of roof blocks, and the concreting of the roof and beams is done in an integrated manner.

Compared to Uboot and Cubiax roofing systems, concreting in Waffle system is done seamlessly and without the use of any type of lubricant.

Waffle roof price

Many factors play a role in the price of the waffle roof, including the time of execution of the work, the material used in the construction of the roof, the cost of contracting, repairs, the cost of raw materials in the construction of beams, unilateral or bilateral molds, roof dimensions and so on. Although the price of this roof is a little higher than conventional roofs, it meets the needs of customers well. If quality materials are used in the construction of this roof, the cost will certainly be higher.