Introduction to all types of building materials

Building materials are materials that are used in the construction and production of various structures. A variety of materials are used in the construction of a building, whether natural or artificial, raw or mixed, each with unique characteristics. Familiarity with these materials is essential for drawing and executing building plans, so construction practitioners must be familiar with building materials to build a durable and durable structure. The most common materials that have been used from the past to the present and still maintain their place in the architectural and construction industry are wood, cement, metal, brick and concrete. These materials are widely used in various projects due to their high strength and low cost. In today’s modern world, modern building materials are produced and marketed by artisans who have innumerable advantages and advantages over traditional materials. Each of these materials, depending on their strength and performance, are used in different parts of the building. Introduction of different types of building materials and their application. Stay with us.

Material types by gender

If we are to classify building materials by sex we can refer to two categories of composite and simple materials.

Simple materials

Simple aggregates are called natural or synthetic aggregates whose ingredients are similar. Materials such as sand, bricks, cement, blocks and more. They are simple ingredients.

Composites

Composite materials are natural or synthetic materials used in the production of some materials. All types of mortar, concrete, isogam, etc. are composite materials.

Types of building materials based on production

Each building material is manufactured and delivered to the consumer in a different way, but in general it can be said that the materials are either manufactured or used locally in the construction industry.

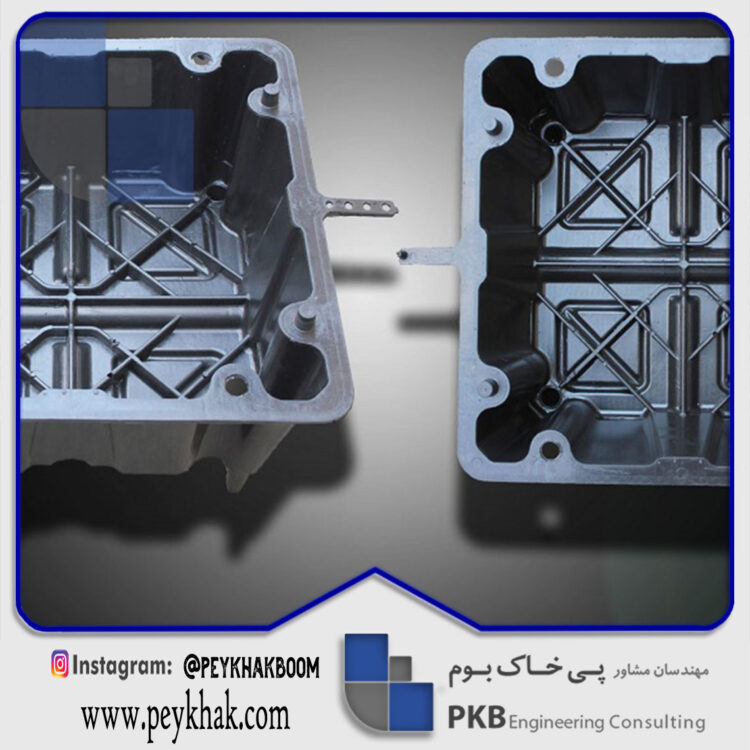

Prefabricated building materials

Prefabricated materials are materials that are manufactured in different factories or workshops and then transported to the project site. By using prefabricated materials, the overall cost of the project and its execution time are reduced. Also, by reducing the amount of construction waste, an effective step will be taken to protect the environment. Although these materials may not be flexible enough to undergo modifications and the early stages of their design and production are time consuming, the importance and efficiency of prefabricated materials in construction cannot be ignored. Prefabricated concrete slabs, prefabricated concrete walls, prefabricated plaster panels, ceramic tiles, types of blocks, bricks, etc. are among the materials that are provided to the manufacturer at the factory.

In-situ building materials

In situ materials As it is known, materials that are produced and used on site for construction projects are used. For example, mortar types, in situ bitumen, building skeletons, in situ frameworks, in-situ concrete, etc., can be mentioned as in-situ materials.

Building materials and their application

Clay

Soil is a combination of fine minerals caused by weathering and the destruction of rocks. The soils are divided into two types of adherent and non-adherent and have fine or coarse aggregates. The most superficial layer of the earth’s surface is soil type, which depends on the weather, the type of primary rock, the activity of organisms and the geographical area. Clay is one of the types of adhesive soils used in construction. This soil is the result of erosion of metamorphic and igneous rocks and is also called colloid because of its very small grains. The key to using this material is to choose a quality sample. Clay is the best material that can be used to control the temperature of a building. The use of clay helps to maintain heat in the building. Since the construction of houses is such that they penetrate the hot or cold air in summer and winter, the use of clay in building construction can be largely effective in stabilizing heat and cold and controlling temperature.

Clay application

Clay is used in the production of bricks, tiles, ceramics, mortar, plaster, lime mortar, straw, clay, etc. The main reason for using this material at an affordable price is its ease of use and its sluggishness.

Rock

One of the materials that has been used in construction since ancient times is stone. Stones are hard and solid materials that consist of one or more minerals and are divided into three general categories of igneous rocks, sedimentary rocks and metamorphic rocks. The main element of all rocks is silica, but depending on the conditions in which they are formed, they will contain different minerals and ingredients. One of the advantages of using this material is its availability.

Types of building stone

The stones have different types that are selected according to their strength and performance and are used in many different ways. To get acquainted with the types of masonry stones you can find in nature include granite, marble, travertine, quartzite, marble, sandstone, gabbro and diorite. In the construction industry, stones are used in both natural (raw) and non-natural (raw) ways. Natural stones are river rocks, carcass stones, layered rocks, and mountain rocks, but the rocks are referred to as rocks that work in different ways depending on their application. . Tablets, polyhedral stones, crustaceans, two-tiered stones, etc. are among these types of rocks.

Application of stone

As you know in our country stone mines are abundant, so in most construction projects this material is used because of its reasonable price, high strength and easy availability. The high variety of rock makes it possible to use this material in various locations. Applications of durable and durable materials such as tunnels, bridges, flooring, foundry, facade, porcelain, interior decoration, stairs and more.

Wood

Wood is a natural material that comes from the heart of nature. This material is used in the manufacture of elements used in construction. It is used in most buildings and in all kinds of weather conditions. Wood has many different types, so the quality of its different types varies. It is even possible that the wood from a sample of a plant or tree may have different qualities. Therefore, different types of wood are used for different purposes. Not bad to know that one of the factors affecting the quality of wood is its growth conditions.

Types of wood

In general, wood can be divided into two categories: natural and artificial:

Natural wood

Natural wood is referred to as forest tree wood, which has a natural color and texture and is found in many different types.

Artificial wood

Artificial wood is the product of natural wood processing and is more widely used than natural wood because of its resistance to water, heat, dust and high diversity. The price of artificial wood is more affordable than natural wood. Artificial wood is manufactured and supplied to customers in various types such as MDF, Polywood, Chipboard and HDF.

Application of wood

Wood is used for a variety of construction purposes, including door and window construction, load bearing members, building facades, flooring, walls, staircases, wooden beams and more.

Brick

Brick is a type of material used in the construction industry that was traditionally obtained from cooking bricks. Traditional adobe bricks were manufactured in both manual and machine ways and provided to the consumer. Bricks can be considered as one of the oldest building materials produced by clay and other materials in high-temperature brick kilns.

Types of brick kilns

The bricks heat according to their raw materials and application in different furnaces, including Hoffman furnace, tunnel furnace, and furnace furnace.

Types of bricks

To get acquainted with the types of bricks you can visit the link below, but briefly the types of these commonly used building materials include:

Ordinary brick

Pressed brick, white brick and Kazakh brick are common bricks used in construction.

Clay brick (clay block)

Clay bricks are lighter in weight than ordinary bricks and are divided into two types of ceiling and wall. In principle, to make it easier to attach to the mortar, it is manufactured in a perforated form.

Welding bricks

Welding bricks are among the bricks that are very resistant to impact, lip banding, abrasion, chemicals, frost and lip filling. Welding bricks used for construction eventually absorb up to 5% water.

Firebrick

Refractory brick is highly resistant to heat, so it is used in environments with high temperatures. The main constituent of this brick is meltable clay. Refractory bricks are free of alkali or lime and are produced in different colors.

Brick Paving

Paving bricks are resistant to abrasion and water absorption and are used for paving various locations and flooring.

Concrete

Concrete is made from a mixture of water and cement, and the cement used is Portland cement. Special vibrators are used when making this product to prevent bubbles from forming which reduce concrete endurance.

Concrete types

heavy concrete

The concrete used to make heavy aggregates is called heavy concrete. The weight of this concrete is between 1 and 2 kg / m3.

Concrete

Lightweight concrete is a concrete whose aggregates are light weight. If the concrete weight is less than 5 kg / m 2, it is considered to be lightweight concrete. Lightweight concrete is used to make concrete blocks.

Porous concrete

Concrete, which has multiple openings and holes for passage of water or air, is called porous concrete.

Pro-concrete style

Aerobic additives are used in the production of this concrete. Lightweight concrete is used in places where concrete can be thawed and solidified.

High strength concrete

High strength concrete has a strength above 1 MPa. When the water-to-cement ratio is reduced, the concrete becomes highly resistant. The mechanical properties of the concrete are very high and chemicals cannot damage it.

Polymer concrete

In this type of concrete, polymer materials are used to bond concrete aggregates, thus eliminating cement in its production. Polymeric materials significantly reduce the volume of cavities between aggregates.

Self-compacting concrete

Self-compacting concrete is a concrete that does not need vibration and is only compressed by its weight. This concrete is used for bulk concreting.

Concrete application

Concrete is a very durable material used for structural reinforcement. Concrete is used in different places according to its type but in general it is used for construction of bridges, dams, floors, tunnels, flooring and more.

Iron

Iron is one of the materials used in construction because of its high strength and high plasticity. In principle, these materials are not used purely, but are used as alloys. Steel, copper, cast iron, aluminum, steel and… are alloys of iron that each have different uses. Iron works increase the durability and strength of the structure, but their only drawback is their lack of resistance to rust and corrosion. Hence, different coatings are used for it.

Application of iron

Iron is used in the manufacture of all kinds of construction tools, beams, sheets, doors, corners, rebar, etc.

Glass

Glass is a light-weight, transparent material that is particularly useful in construction applications. Sand and silicates are used in the manufacture of this product. This material is very fragile, so stabilizers are used in its production to increase its resistance to various factors. Types of glass include colored glass, double glazed glass, fireproof glass, fireproof glass, secured glass, bent glass, reflex glass, opaque smart glass, etc. and are selected and used for different purposes depending on the strength. Opaque smart glass is one of the glassware used in today’s smart home. This glass adjusts the amount of light entering the building. For example, it automatically blurs during the day and returns to its original state at night. Smart glass significantly reduces the heating and cooling costs of a building.

Types of glass

Glasses are manufactured in different types for different applications. The most common glass used in the building is as follows:

Colored glass

The glass, as its name implies, comes in a variety of colors, absorbing the greatest amount of light and passing a small amount of it.

Deluxe glass

The glazed glass acts as a mirror. During the day, these jars block the view from inside the building but at night they lose their ability. Reflective glass reflects light spectrum and prevents it from entering the building.

double glazed window

The glass is made of two layers of glass, with space between them filled with argon gas. These jars play the role of thermal and sound insulation for the building and are very effective in reducing energy loss.

Laminated Glass

Unlike ordinary glass, when shattered by impact, the glass is not scattered around because it has a nylon layer between the layers of glass that holds the glass pieces together. Laminated glass is the most durable glass, consisting of several layers of glass that are bonded under pressure and heat by nylon layers.

Tempered glass

Secure glass is a type of glass that is produced by heat and cold. This glass can be used in places where heat and safety are important. In the construction industry, security glass is used to make door frames or places where human safety is significant.

Bent glass

The bent glass is of great interest to architects because of its arch shape. For example, the use of these glass panels for staircase wall panels demonstrates the incredible beauty of space.

Application of glass

Glass is used in door and window making, building facades, mirror making, skylights, glass tile, glass blocks, decorative elements, and more. These days, double glazing is used in door and window construction and reflex glass for building facades. The Curtain Wall facade is one of the all-glass views that give the city a unique look.

Plaster

Gypsum is a soft, white powder obtained from gypsum. It is derived directly from gypsum and no additives are used in its production.

Types of plaster

Plaster used for construction purposes are as follows:

White Plaster

The price of bleach plaster is very reasonable. This plaster is used to cover the surface and whiten the walls and the color is completely white.

Micronized plaster

This gypsum is produced from conventional gypsum processing. Micronized gypsum is used for killing, bleaching, plastering, etc.

Ivory plaster

Ivory plaster has a very fine grain size and long retention time. This material is used for killing the building, making prefabricated plaster panels, and so on.

Chipboard plaster

The adhesion of this type of gypsum is higher than other gypsum. This plaster can be applied on a variety of surfaces such as concrete blocks, foam surfaces, porous concrete surfaces and so on.

Gypsum plasterboard

It has good moisture resistance and prevents heat and sound transmission. Siwa gypsum comes from the combination of micronized gypsum with other additives. This type of plaster is suitable for underlayment.

Application of plaster

Plaster material is premature and used for mortar, whitewashing of walls and walls, building prefabricated panels, decorative elements and more.

Cement

Cement is a widely used material composed of calcareous materials such as aluminum oxide and silicon. It is produced in a very soft powder and is either bulked or packaged. Combining cement with water creates a hard material called concrete, which plays an important role in the reinforcement of various structures.

Types of cement

Portland cement

Portland cement is one of the best quality cement used in construction. These cements are of type 1 to 4, each of which can be used in different locations depending on the capabilities and capabilities required.

Colored cement

Colored cement is created by adding pigments to white cement. This cement creates a smooth and uniform surface, so it is the best option for building facade coatings. The colored cement has high mechanical strength and does not crack.

Refractory cement

Refractory cement retains its resistance to high temperatures and heat shock, corrosive substances, sulfates, abrasion, impact, acidic water and so on. This cement hardens earlier than Portland cement.