You must have often passed by a semi-finished building under construction where engineers and workers were working and transporting building materials. Some workers pick up sacks from behind the truck and put them on their shoulders and take them inside the building, others throw bricks upwards or use a freon with a rope to top the pulley, other building materials To the upper floors and thousands more.

The question is, have you ever paid attention to the building materials that workers carry? Have you thought about why a particular material is used in any building, and what’s the difference between them?

For the answer to this question, follow us on in this article.

Building materials in construction

Building materials are the basic tools in building a building. There is no building that will form its structure without using the simplest materials, and on the other hand the quality of each building depends on the type of materials used in its construction. The materials you see in the normal are the simplest types to use, but in general and so-called specialized materials, these materials are divided into different categories that have physical, chemical, and other properties.

Naturalization of building materials

All of the building materials come from nature and mines, and after chemical changes, they become the materials you want to see, and that’s what you see today. Today, however, with the advent of industry and technology, the type of materials used has changed from traditional to modern, and we have even seen major changes in their structure and form, especially in the use of brick and stone. There may have been no change in their usage, but their shape and appearance have changed a lot compared to the past.

Types of building materials

Building materials can be divided into several categories for some properties.

The first is a gender division that is simple and compound.

Simple materials

Materials are the same for all materials used, such as sand, sand, cement, beam tile

Composites

Materials that are processed and used in materials of different materials, such as concrete, iran, isogam, mortar and …

Another segmentation is in terms of prefabricated and in-situ building materials.

Assembled

There are building materials that are manufactured in the factory itself, such as tile, stone, brick, joinery, block, etc.

in place

There are materials made at the same construction site, such as mortars

Another classification is in terms of its origin and application

Natural materials

Substances that exist in the heart of nature and use them in the same way as clay

Adhesives

Materials used as adhesives for gluing other materials such as cement plaster

Mortar

Are a kind of adhesive material that comes from the combination of several substances and adhesives, such as clay

Parts

Tools used in construction as components, such as stone

Organic materials

Hydrocarbon materials derived from the decomposition of animal carcasses and plant residues, such as asphalt

Other materials

Materials such as wool, which are components of a building but cannot be assigned a category.

Here are some of them:

Cement

Cement from building materials supplied in white powder and colored worm bags. The property of cement is that when combined with water it becomes a very durable material and due to the cement’s resistance to heat, humidity, etc., it is used as the best material in the construction industry and cement is one of the key building materials. .

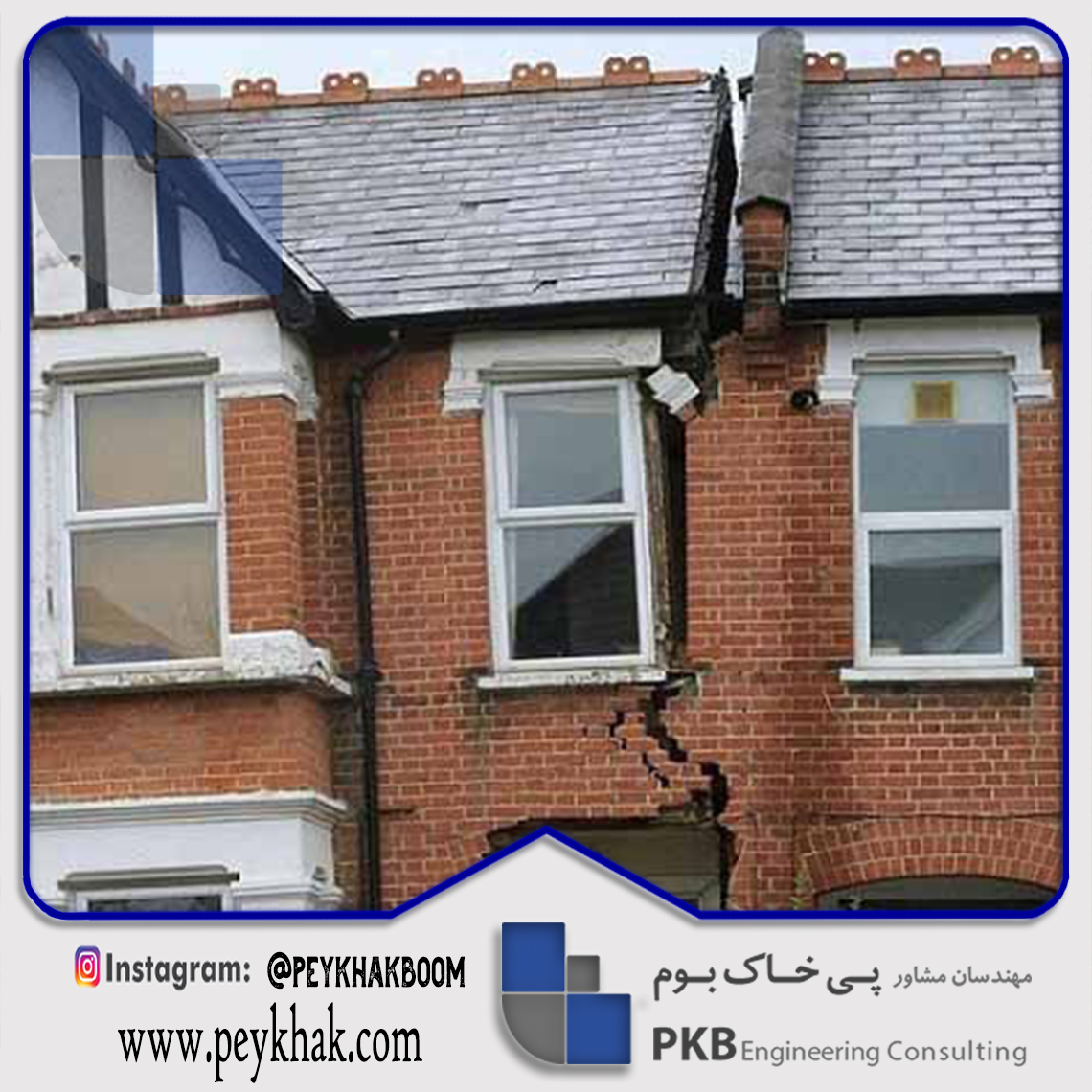

Brick

Brick is a simple building material that is made of both calcareous and clay. In calcareous type, siliceous aggregates are used and in clay type aluminum silicates are used; however, the basis of brick formation is clay.

In the past, bricks were mostly used for interior wall construction, but today they are also used as an interior decorative tool, although the type of brick is known as refractory brick, which has a higher resistance to conventional type.

Metal

Most of the metal used in construction is steel. Weldability and flexibility are high hardnesses with unique steel properties that are more commonly used in rebar production. If you are careful, steel is used in the building.

Plaster

The plaster that you use as a building material is actually powder. Gypsum powder is a white substance and, like cement, becomes a stiff material after being mixed with water. Plaster is used for whitening, surface smoothing, tiling, ceramics, false ceiling production, etc. In fact, the white walls that most of you see when a building is finished are the plaster that is on the brick.

Wood

Wood is actually a type of building material used in interior design. The most important use of wood is in the manufacture of wooden cabinets. The wood used for this purpose has properties such as resistance to air and water decay, cracking, bacterial growth and especially termites, etc.

Rock

Stones are other building materials that are used inside the building as well as the facade of the building. Today, however, stones are mostly used in the exterior decoration of buildings. Corrosion resistance and temperature and beauty changes are two important factors used in construction

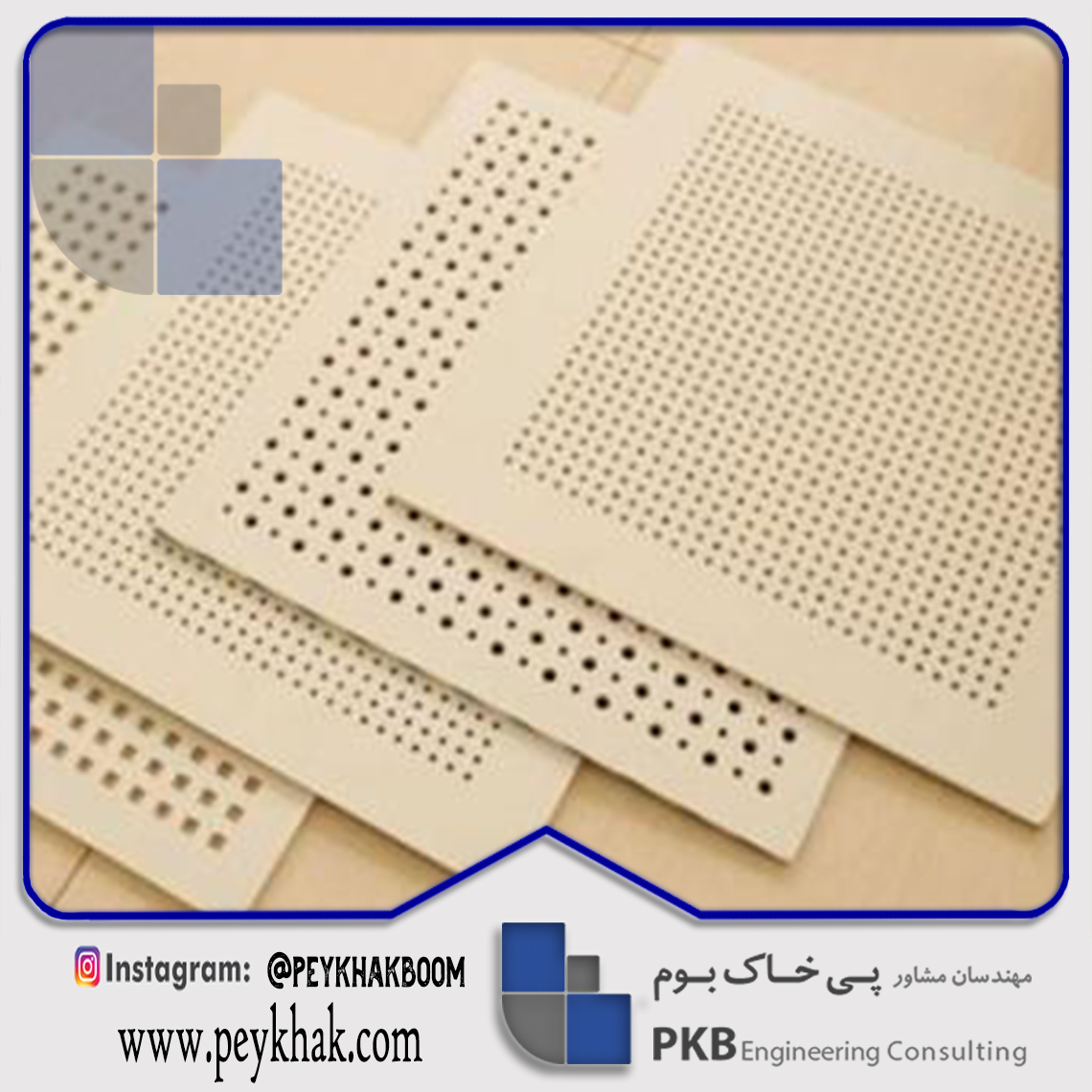

Soil

The soil used in construction is quite different from the one you see on the street. Soil definitions have a diameter of less than 0.002 mm. Clay is the most common type of soil that you have ever heard of, and it is also an important building material. Clay is a soil that has a sticky state, and if it does not, it is called sand. The reason for using clay is that it does not pass through water and that is why it is used in places such as roofs for waterproofing.