The foundation or foundation of a building is one of the essential components of any structure and its task is to withstand the pressure caused by the columns and transfer this force to the ground. According to the type of structure and the location where it is to be carried out, the construction is performed under different conditions to provide the strength and strength of the structure. The foundation is the first stage of construction and the standards required for its implementation must be met. In previous posts, the builder introduced the types of building foundations, and now we are going to explain the foundation formatting for you. Stay with us.

Foundation formatting

In molding foundations, wood, metal, and brick molds are used, each with its own unique characteristics. In the formatting system, different panels are used for formatting, which can be created in different shapes depending on the type of structure and the execution plan. The foundation for the building after excavation needs to be axed and the mold positioned on the ground to allow the foundation to be laid. Among the points to consider in formatting a foundation are the following:

The molds need to be firmly fixed and secured.

Consideration of the dimensions of the foundation is very important in choosing the mold.

The molds should be designed and manufactured so that they can be easily installed or opened quickly and easily. This will save you considerable time and money.

Appropriate sealing should be done to prevent the loss of concrete sap.

Mold oil should be used to improve the quality of concrete surface and mold strength.

Molds must be of high durability so that they can withstand the pressure and loads without breaking or squeezing the concrete.

When considering whether a foundation is a facade, attention must be paid to determining the quality of building materials and formatting.

The molding and mounting of the molds must be such that the dimensions, shape and appearance of the concrete are achieved.

Placing the foundation and adhering to the cover of reinforcement are also important points in forming a foundation.

Templates must be selected in such a way that they can be transported and accommodated with available facilities.

The templates used to lay the foundation include:

Metal molding

Metal molds have better strength and surface roughness than wood and brick molds. Nowadays, these types of molds are among the most common molds used in building construction because they can be easily transported and used in any type of operating system. The advantages of metal molding include high durability, ease of connection, high speed of operation, reusability and high productivity. Metal projects are the best option in projects where the dimensions and dimensions are low but the workload is high. Although the initial price of these molds is expensive, they are long lasting and can be used for many years. In order to prevent adverse weather effects on these molds, they should be even insulated.

Types of formatting in foundation implementation

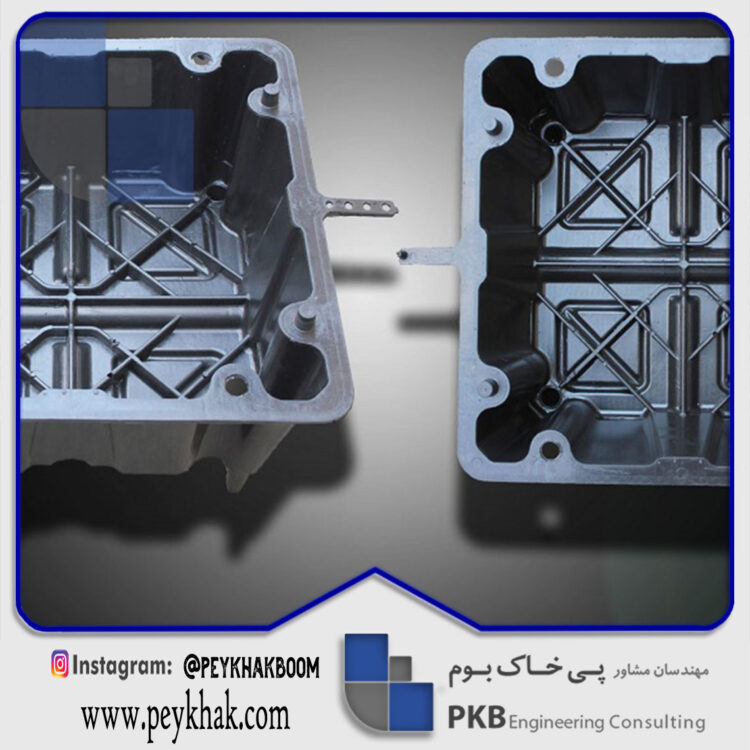

Metal Mold Components

What are known as metal molding components are various components for concrete molding. These components can be different in different projects. Examples of metallic mold components include cast iron bolt, case washer, ball strap, coarse-grained metal longitudinal clamp, double screw jack and so on.

Brick molding

This type of mold is used around the foundation, and after the concrete has been retained, remains in the desired location and is considered a permanent mold. To prevent the concrete from being squeezed by brick, a layer of nylon sheet before the concrete is required. Finish install on the wall, otherwise the bricks should be thoroughly sprayed. However, when spraying, the fact that water should not accumulate in molds should be kept in mind.

In this type of formatting, the boundaries of the structural axes and molds must be specified by the surveyor. To avoid the slightest error in performing this type of formatting, it is advisable to nail the corners of the axes and templates and paint the border of the molds after it has been marked with a string. In addition, the ground surface must have a uniform alignment, which is done by mapping. When brick molding, a thin layer of cement must be applied to the inner wall of the mold, but plastic can also be used if not. The back of the brick mold can be filled with dirt.

Wooden Molding

The wooden mold, as its name implies, is made of wood. Molds are made enough to be transported to the desired location. Concrete molding in these molds requires sufficient care to prevent damage to their edges. Wooden molds are lighter in weight than metal molds, but their resistance to moisture is not high. The benefits of this type of mold include ease of execution and connections, low thermal coefficient and light weight. The only disadvantage of not using a wooden mold more than 3 times.

Concrete Molding

What should be taken into account in concrete molding is the strength of the molds and their proper bracing. To increase the durability of the scaffold, the use of longitudinal and transverse straps is required. Concrete molding should be designed to prevent the concrete from getting out of them. Molds must be cool to run concrete. If the formatting is hot, it reduces the quality of the concrete and changes its color. This causes the concrete to lose its proper shape.

What is a Modular Mold?

Another name for the concrete mold is the modular mold. This type of molding is manufactured in various sizes and is used in the molding of concrete structures.

Concrete mold fittings

Parts are needed to connect the concrete mold and create a suitable concrete structure. Components needed to do this are clamps, medium and long clamps, tube-to-tube clamps, ballet, cane ball, medium clamp, cast iron bracket and so on.