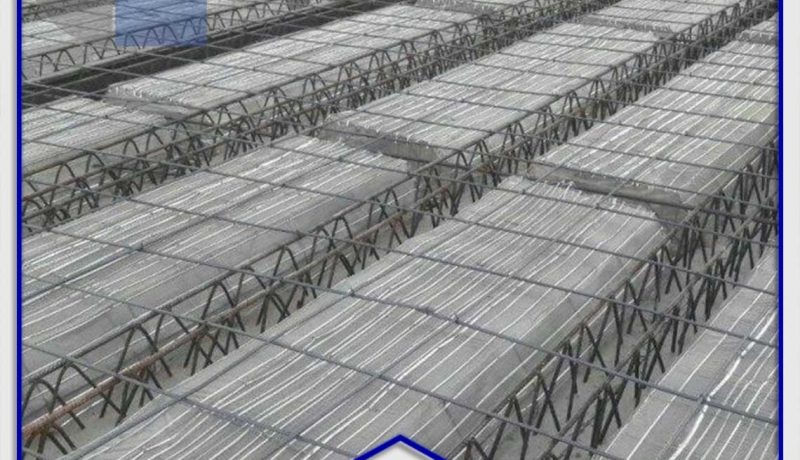

Among all the roofs of the building, block joist roof is the most widely used type of roof. In block roof beam system, the beams act as a side beam and the block is the filling agent between the beams. In the roof of the block beams, lightweight concrete, clay or polystyrene foam hollow blocks are used to fill the empty space between the beams. Beam and block roofs are one-sided slabs that use hollow blocks to reduce dead load on the building. In this type of roof, beams are used in two types of concrete or steel and the distance between them is about 50 cm. In general, in the construction of beams, practical calculations should be made based on the customer’s order.

Beam and block roofs are made using beams and blocks that are prefabricated in the factory and are executed by concrete concreting stage. After placing the beams at certain distances and piling under the beams, the blocks are arranged between the two beams. Then the thermal reinforcements are installed and concreting operations are performed.

Beam and block roof components include the following:

• Beams

• Block

• Negative armatures and heat and drop armatures

• Middle coil

• Concrete cover in place

Beam block roofs are used in a variety of buildings, including brick buildings, metal and concrete structures, and have the following benefits and advantages:

Advantages of joist beam and block roofs

• Execution of block joist roof does not require specialized labor or special equipment and can be done by ordinary building workers.

• Candlelighting during roofing makes these types of roofs have less vibration than other roofs.

• Forming under ceilings is done only by piling and installing four lathes at certain distances, and there is no need for specialized people who formulate and reinforce reinforced concrete roofs.

• Installation of block joist roof is done quickly and easily due to prefabricated beams and blocks.

• Implementation of this ceiling does not require time-consuming workshop and costly work.

• Beams and blocks are produced in industrial factories under the supervision of quality control, and less manpower is required to do so.

• The use of hollow blocks reduces the consumption of concrete, which saves money and is economically viable.

• These roofs are highly resistant to horizontal forces such as wind and earthquake.

• The beams of the blocks are light weight and their transportation does not require the use of cranes because they can be transported to the floors by the workers.

• Stretch concrete in beam and block roofs are replaced by blocks, which is why these types of roofs are economical.

• With the implementation of beam and block roofs, it is possible to run several roofs simultaneously and there is no need to use sub-roof jacks.

• The use of this type of roof reduces the consumption of plaster and soil and creates more uniformity under the roof.

• Block joist roofs are a kind of sound, heat and moisture insulation.

• The strength and durability of block joist roofs against fire is very high.

Concrete beams

Concrete beams are prefabricated elements made of concrete and steel reinforcement. In their structure, the blocks are placed between the beams and covered with concrete. According to the production method, concrete beams fall into two categories: truss and prestressed.

Concrete beam prices

The price of concrete beams varies depending on its length and height. For information on the latest prices of concrete beams, refer to the following link.

Concrete heel beam

The concrete part of the truss is called the concrete heel. This part is where the concrete is placed and acts as a cover and restraint for the lower truss rebars. Concrete heel beams are very important in the execution of the roof, and if there is a problem in its structure, the placement of the blocks will be difficult.

Chromite beams (metal beams)

The chromite beam, also known as the metal beam, consists of a belt or sheet and two wings at the top and bottom. One of the advantages of using chromite beams is to increase the speed of roof execution. Generally, the weight of these beams should not exceed 10 kg with residential loading and the use of 5 to 6 meter beams.

Chromite beam prices

One of the factors influencing the price of chromite beams is its length.

Industrial beams

What is an industrial beam? Industrial or machine beams consist of a floral truss whose cutting rebars are connected to the lower and upper reinforcements using a welding point. One of the effective factors in the price of industrial beams is its length and dimensions.