Building materials are materials that are used in the construction and production of various structures. A variety of materials are used in the construction of a building, whether natural or artificial, raw or mixed, each with unique characteristics. Familiarity with these materials is essential for drawing and executing building plans, so construction practitioners must be familiar with building materials to build a durable and durable structure. The most common materials that have been used from the past to the present and still maintain their place in the architectural and construction industry are wood, cement, metal, brick and concrete. These materials are widely used in various projects due to their high strength and low cost. In today’s modern world, modern building materials are produced and marketed by artisans who have innumerable advantages and advantages over traditional materials. Each of these materials, depending on their strength and performance, are used in different parts of the building. Introduction of different types of building materials and their application. Stay with us.

Material types by gender

If we are to classify building materials by sex we can refer to two categories of composite and simple materials.

Simple materials

Simple aggregates are called natural or synthetic aggregates whose ingredients are similar. Materials such as sand, bricks, cement, blocks and more. They are simple ingredients.

Composites

Composite materials are natural or synthetic materials used in the production of some materials. All types of mortar, concrete, isogam, etc. are composite materials.

Types of building materials based on production

Each building material is manufactured and delivered to the consumer in a different way, but in general it can be said that the materials are either manufactured or used locally in the construction industry.

Prefabricated building materials

Prefabricated materials are materials that are manufactured in different factories or workshops and then transported to the project site. By using prefabricated materials, the overall cost of the project and its execution time are reduced. Also, by reducing the amount of construction waste, an effective step will be taken to protect the environment. Although these materials may not be flexible enough to undergo modifications and the early stages of their design and production are time consuming, the importance and efficiency of prefabricated materials in construction cannot be ignored. Prefabricated concrete slabs, prefabricated concrete walls, prefabricated plaster panels, ceramic tiles, types of blocks, bricks, etc. are among the materials that are provided to the manufacturer at the factory.

In-situ building materials

In situ materials As it is known, materials that are produced and used on site for construction projects are used. For example, mortar types, in situ bitumen, building skeletons, in situ frameworks, in-situ concrete, etc., can be mentioned as in-situ materials.

Building materials and their application

Clay

Soil is a combination of fine minerals caused by weathering and the destruction of rocks. The soils are divided into two types of adherent and non-adherent and have fine or coarse aggregates. The most superficial layer of the earth’s surface is soil type, which depends on the weather, the type of primary rock, the activity of organisms and the geographical area. Clay is one of the types of adhesive soils used in construction. This soil is the result of erosion of metamorphic and igneous rocks and is also called colloid because of its very small grains. The key to using this material is to choose a quality sample. Clay is the best material that can be used to control the temperature of a building. The use of clay helps to maintain heat in the building. Since the construction of houses is such that they penetrate the hot or cold air in summer and winter, the use of clay in building construction can be largely effective in stabilizing heat and cold and controlling temperature.

Clay application

Clay is used in the production of bricks, tiles, ceramics, mortar, plaster, lime mortar, straw, clay, etc. The main reason for using this material at an affordable price is its ease of use and its sluggishness.

Rock

One of the materials that has been used in construction since ancient times is stone. Stones are hard and solid materials that consist of one or more minerals and are divided into three general categories of igneous rocks, sedimentary rocks and metamorphic rocks. The main element of all rocks is silica, but depending on the conditions in which they are formed, they will contain different minerals and ingredients. One of the advantages of using this material is its availability.

Types of building stone

The stones have different types that are selected according to their strength and performance and are used in many different ways. To get acquainted with the types of masonry stones you can find in nature include granite, marble, travertine, quartzite, marble, sandstone, gabbro and diorite. In the construction industry, stones are used in both natural (raw) and non-natural (raw) ways. Natural stones are river rocks, carcass stones, layered rocks, and mountain rocks, but the rocks are referred to as rocks that work in different ways depending on their application. . Tablets, polyhedral stones, crustaceans, two-tiered stones, etc. are among these types of rocks.

Application of stone

As you know in our country stone mines are abundant, so in most construction projects this material is used because of its reasonable price, high strength and easy availability. The high variety of rock makes it possible to use this material in various locations. Applications of durable and durable materials such as tunnels, bridges, flooring, foundry, facade, porcelain, interior decoration, stairs and more.

Wood

Wood is a natural material that comes from the heart of nature. This material is used in the manufacture of elements used in construction. It is used in most buildings and in all kinds of weather conditions. Wood has many different types, so the quality of its different types varies. It is even possible that the wood from a sample of a plant or tree may have different qualities. Therefore, different types of wood are used for different purposes. Not bad to know that one of the factors affecting the quality of wood is its growth conditions.

Types of wood

In general, wood can be divided into two categories: natural and artificial:

Natural wood

Natural wood is referred to as forest tree wood, which has a natural color and texture and is found in many different types.

Artificial wood

Artificial wood is the product of natural wood processing and is more widely used than natural wood because of its resistance to water, heat, dust and high diversity. The price of artificial wood is more affordable than natural wood. Artificial wood is manufactured and supplied to customers in various types such as MDF, Polywood, Chipboard and HDF.

Application of wood

Wood is used for a variety of construction purposes, including door and window construction, load bearing members, building facades, flooring, walls, staircases, wooden beams and more.

Brick

Brick is a type of material used in the construction industry that was traditionally obtained from cooking bricks. Traditional adobe bricks were manufactured in both manual and machine ways and provided to the consumer. Bricks can be considered as one of the oldest building materials produced by clay and other materials in high-temperature brick kilns.

Types of brick kilns

The bricks heat according to their raw materials and application in different furnaces, including Hoffman furnace, tunnel furnace, and furnace furnace.

Types of bricks

To get acquainted with the types of bricks you can visit the link below, but briefly the types of these commonly used building materials include:

Ordinary brick

Pressed brick, white brick and Kazakh brick are common bricks used in construction.

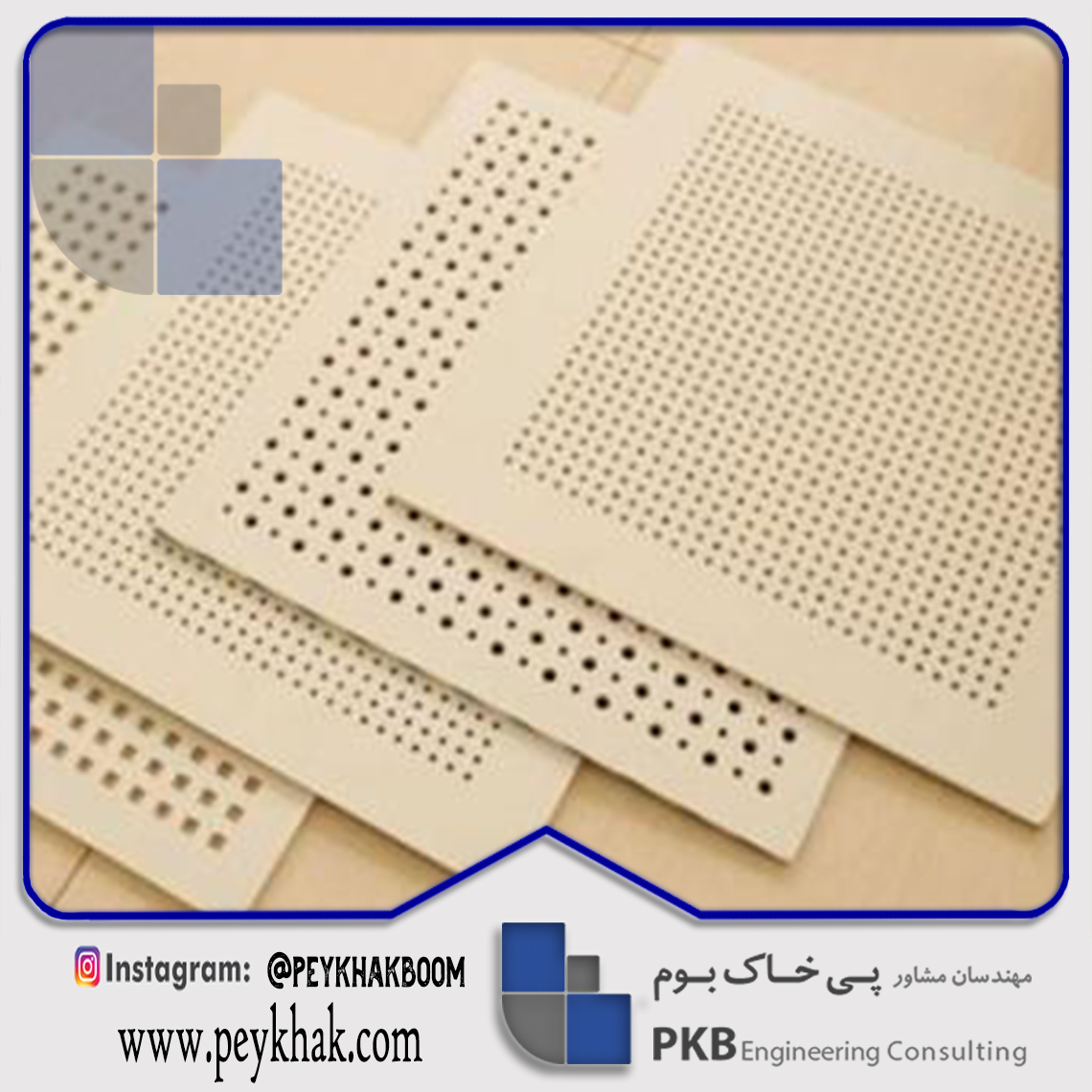

Clay brick (clay block)

Clay bricks are lighter in weight than ordinary bricks and are divided into two types of ceiling and wall. In principle, to make it easier to attach to the mortar, it is manufactured in a perforated form.